Europe’s Accelerating Renewable Transition

Europe is rapidly accelerating its transition toward renewable energy, with wind power playing a central role in the future electricity system. By 2025, wind energy is projected to become the European Union’s main source of electricity, supplying up to 50% of total power demand. This shift reflects the scale and speed at which wind energy capacity is being deployed across Europe to support decarbonisation and long-term energy security objectives.

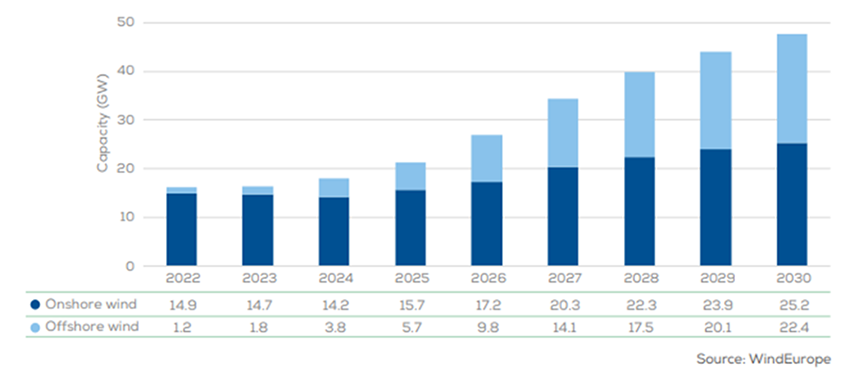

Offshore wind is a key driver of this transformation. Projections indicate a steady increase in both onshore and offshore wind capacity under the REPowerEU scenario, with offshore wind contributing an increasingly significant share of new installations toward 2030 and beyond. Within this expansion, floating offshore wind is expected to play a growing role, particularly as development moves into deeper waters where fixed-bottom solutions are less viable.

By 2050, floating offshore wind is expected to reach a total installed capacity of approximately 264 GW, accounting for around 15% of total offshore wind generation. This highlights the strategic importance of floating wind technologies in meeting Europe’s long-term energy needs. As offshore wind deployment continues to accelerate, floating solutions will be essential to unlocking additional capacity, supporting system resilience, and enabling Europe to fully harness its offshore wind resources.

Figure 1. Build out capacity of wind energy in the EU under the REPowerEU scenario

Opportunities in Floating Offshore Wind Deployment

As Europe ramps up offshore wind, attention is turning to floating offshore wind technology – a frontier with huge promise. Traditional bottom-fixed turbines are limited to relatively shallow waters (typically under ~60 metres depth), but most of Europe’s best wind resources lie farther offshore in deeper waters. In fact, roughly 80% of the world’s offshore wind potential is in locations deeper than 50 m, which require floating platforms. By enabling turbines to be installed in deep sea areas, floating designs open vast new regions for development. This is especially meaningful for countries with deep maritime zones where conventional fixed turbines aren’t feasible – for example, floating wind farms can tap strong wind in the Atlantic, Mediterranean, and other deep-water basins, allowing more European nations to harness offshore wind. In short, floating turbines greatly expand the geographic scope of offshore wind, unlocking higher wind speeds and larger areas that were previously out of reach.

Europe is poised to capitalize on this opportunity. It has already launched several pilot projects proving the concept of floating wind, and the coming years will see a rapid scale-up. Today, only a few small floating wind farms exist (on the order of just hundreds of megawatts in total across Europe). However, many countries have announced dedicated plans and targets for floating wind by 2030. As a result, industry experts predict Europe could have over 10 GW of floating wind operating by 2030. Looking further ahead, floating turbines are expected to become a significant portion of all new offshore wind installations. Analyses suggest that to achieve Europe’s climate neutrality, the EU may need up to 150 GW of floating offshore wind by 2050. This presents a tremendous opportunity for European technological leadership: by investing now in floating wind, Europe can lead a vast and untapped global market while securing abundant clean energy for decades to come.

Challenges in Floating Offshore Wind Deployment

Despite its strong potential, floating offshore wind faces several important challenges that must be addressed before large-scale deployment can be achieved. One of the most significant barriers is the higher upfront cost compared to fixed-bottom offshore wind. Current floating wind projects typically require 30–50% higher capital expenditure (CAPEX), driven by the cost of floating platforms, mooring systems, specialised installation procedures, and lower levels of industrial standardisation. As a result, the levelised cost of energy (LCOE) for floating wind currently spans a wide range, estimated at approximately 95–160 €/MWh, reflecting the early-stage nature of the technology and the diversity of design concepts under development.

Another major challenge is the emerging supply chain for floating offshore wind. Unlike fixed-bottom offshore wind, which benefits from decades of industrial scaling, floating wind relies on supply chains that are still developing. Production capacity for key components such as floating platforms, mooring systems, and specialised vessels remains limited. These constraints can create bottlenecks, increase project timelines, and add uncertainty for developers planning large-scale deployments. Strengthening and expanding the supply chain will be essential to support future growth.

Grid connection complexity also poses a challenge, particularly for floating wind farms located far offshore. Greater distances from shore increase the need for advanced transmission solutions, including high-voltage direct current (HVDC) systems and associated grid upgrades. Integrating large volumes of offshore electricity into existing onshore grids requires careful planning and investment to ensure system stability and reliability.

Finally, floating offshore wind must operate in challenging environmental conditions. Harsh marine environments, characterised by strong winds, waves, and corrosive conditions, place high demands on turbine structures and floating platforms. These conditions make inspection, repair, and maintenance more complex and costly. In many cases, operation and maintenance activities can account for 50–80% of total operational expenditure (OPEX), highlighting the importance of designs that improve accessibility, reliability, and durability.

Opportunities for Vertical Axis Wind Turbines (VAWT)

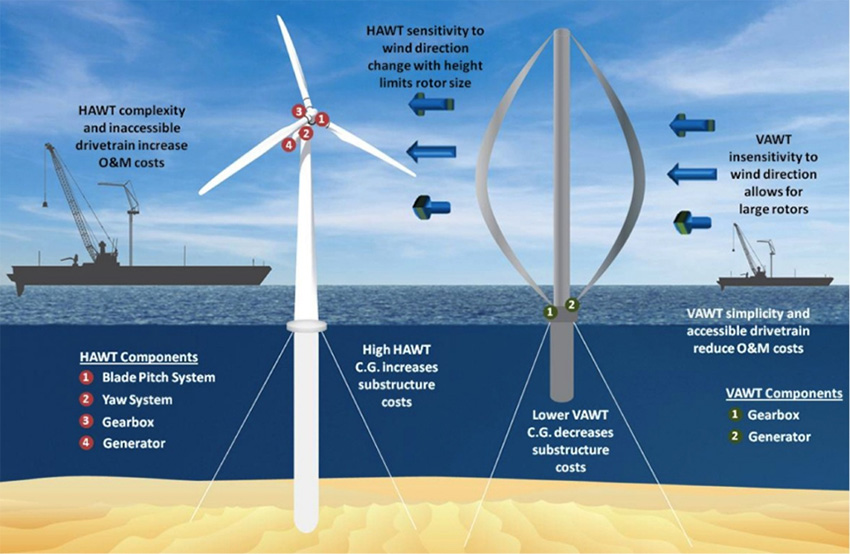

One innovative pathway to address some of the challenges of floating wind is the use of vertical axis wind turbines (VAWT). Unlike the conventional three-bladed horizontal-axis turbines, a vertical axis turbine spins around a vertical column – think of it like a spinning carousel rather than a horizontal-axis windmill. This alternative design has notable inherent advantages that become especially attractive offshore. First, VAWTs are omni-directional, meaning they don’t need to rotate or yaw to face the wind. Eliminating complex yaw mechanisms simplifies the turbine’s design and reduces maintenance needs. Second, a vertical-axis turbine’s heavy components (generator, gearbox, etc.) can be placed at the base of the structure, near the waterline, instead of atop a high tower. This yields a much lower centre of gravity, which greatly improves stability on a floating platform. A lower centre of gravity and centre of pressure allow the use of smaller, less expensive floaters to support the turbine. In practical terms, the platform can be lighter and cheaper while keeping the turbine upright in rough seas. Additionally, having the machinery close to the surface means easier access for maintenance; crews can service the generator and other critical parts from the platform level, without requiring giant cranes or towing the unit back to port. These design features give VAWTs the potential to reduce operational and maintenance costs compared to today’s horizontal-axis designs. In short, by rethinking the turbine architecture, vertical-axis designs promise to tackle some of the cost and logistical issues that challenge floating wind deployment.

While vertical-axis turbines have been tested on a small scale onshore (and historically faced difficulties achieving high efficiency and scalability on land), the offshore context offers a fresh opportunity for this technology. The benefits of VAWT – no yaw system, improved stability, and maintenance access – align well with the needs of floating wind farms. Recognizing this potential, the EU is investing in projects to prove the concept at scale. This is evident in the VERTI-GO project, which is developing a full-scale floating VAWT system. VERTI-GO’s design combines the turbine tower and floater into a single integrated structure purpose-built for offshore conditions. This integrated approach is expected to simplify maintenance, reduce downtime, and lower costs by enabling a leaner, more robust platform. The project builds on successful trials of a smaller prototype – a 30 kW demonstrator – and now aims to scale up to a 2 MW vertical-axis floating wind turbine to be tested in real sea conditions for 15 months. By the end of the project, the team expects to validate that such a design can achieve performance and reliability comparable to conventional turbines, but with significant operational advantages. In essence, VERTI-GO’s anticipated results will show how vertical-axis technology can deliver an efficient, cost-effective floating wind solution for Europe’s clean energy future.

Figure 2. HAWT vs VAWT showing main components (figure from Sandia National Laboratories)